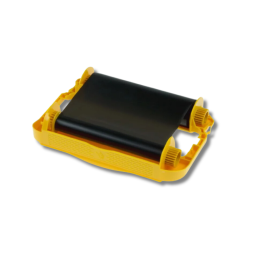

What is a thermal transfer ribbon?

The ribbon is the consumable required for printing. It consists of several layers:

- The first is the polyester base film which is heated by the printer,

- The second layer is the release liner which allows the ink to come off the film more easily.

- Finally, the last layer is the ink that is transferred to the substrate. Its technical properties differ depending on the ink chosen and its quality.

There are different types of ink that are not suitable for all surfaces. Thermal transfer ink is applied to the label by the heat generated by the print head. The heat heats up the ink on the transfer film, which is then bonded to the label backing - whether it is vellum or synthetic.

Please note that ribbons are only useful for thermal transfer printing. There is no need for ribbons in direct thermal printing, which only requires a heating head and a heat reactive label. This printing technique is recommended for short-term labels, such as shipping labels. Its low cost and fast printing are perfectly suited to the requirements of a very short term label.

If you want to print in colour, the most suitable printing technique is inkjet.

The different qualities of thermal transfer ribbons

The ribbons are the consumables that will guarantee the durability of your label over time. Their choice is not trivial and it is essential to ask yourself the right questions before choosing the type of ink required.

This summary table shows you the 3 main qualities of ink available on the market.

| Type of ink | Quality | Resistance | Areas of application | Recommended use |

|---|

| Wax Resin Ribbons | universal quality for use on all types of adhesive labels (synthetic + coated paper) | resistance to scratching and aggressive products | food, health, pharmaceutical, stock management and logistics, horticulture, retail, outdoor use. | clothing labels, industrial labelling, horticulture and identification wristbands. |

|---|

| Resin ribbons | quality specially developed for printing on synthetic labels | the most resistant: to scratches, stains, heat (up to 150°), weather and chemicals | automotive, food, healthcare, pharmaceutical, warehouse management and logistics, outdoor use, chemical industry, electronics | extended use wristbands, labelling of chemical containers and engines, identification of sea containers, flexible packaging |

|---|

| Wax ribbons | quality that can be used on paper labels (vellum, matt or glossy). | chemical resistant | agroalimentaire, santé, gestion des stocks et logistique, pharmaceutique, vente au détail, industrie cosmétique. | shipping, transport, identification and marking of prizes. |

|---|

Each type of wax also has different qualities that differ in melting temperature, UV resistance, etc.

All of these inks can be used on all thermal transfer printers, simply by changing the head heating temperature and print speed for maximum print quality.

SBE Direct only offers synthetic labels, therefore our range consists exclusively of wax/resin and resin ribbons.

How do I choose a thermal transfer ribbon (wax, resin, mixed)?

As seen below, there are 3 types of ink. To choose your ribbon, the first step is to identify the quality that suits you. To identify your needs, here are the 4 questions to ask yourself:

- Label life: A synthetic label is intended to last over time. On the contrary, a vellum label is ideal for a short life span.

- Type of label substrate: Depending on the label, the substrate will not be able to accommodate it. For synthetic labels, we recommend wax/resin and resin inks. Wax ink is more suitable for vellum.

- Resistance to external influences: Depending on where the label is to be applied, it must have a certain resistance. For labels left outdoors, resin is the best quality.

By answering these questions and comparing it to the table above, it will be easy to make a choice!

Which thermal transfer printers for which ribbons?

Printers are the most important tool in printing and it is worth asking the right questions before choosing one.

It should be noted that the printer should not be chosen according to the ribbon but rather the other way round. Nevertheless, it is important to define your needs in order to know which printing mode is necessary: thermal transfer or direct thermal transfer.

However, as previously stated, there are many brands and models of thermal transfer printers: Zebras, CAB, Sato, Honeywell, etc.

Once you have identified the ink quality, you need to choose the right ribbon, which is intrinsically linked to the thermal transfer printer.

- the size of my label (width): the width of the ribbon chosen must be greater than that of your label.

- the printer core: the core is the support for the ink film. Printers only support certain core sizes, so check before you buy!

- The maximum size of the roll diameter supported by the printer: the rolled film can have variable diameters and it is indicated the maximum diameter that your printer allows. If you take a larger roll, the ribbon will not rotate on the spindle and will therefore be unusable.

- Inner or outer ink ribbon (in or out): this information informs about the winding direction of the inked side. For a ribbon with external inking (out or CSO) it is the external side of the ribbon that contains the ink, whereas for the internal (in or CSI) it is the internal side. This changes the position of the ribbon in the printer. Most printers now support both ink directions.

To have more durable labels over time, we recommend using clear stock label protectors.

This label protector offers 3 major advantages at a very low cost: it will greatly increase the life of your labels especially in harsh environments, it will reinforce the adhesion of the original label, and finally it will give your labels a glossy finish.

To find out how compatible our printers are with your ribbons, we have written a detailed article.