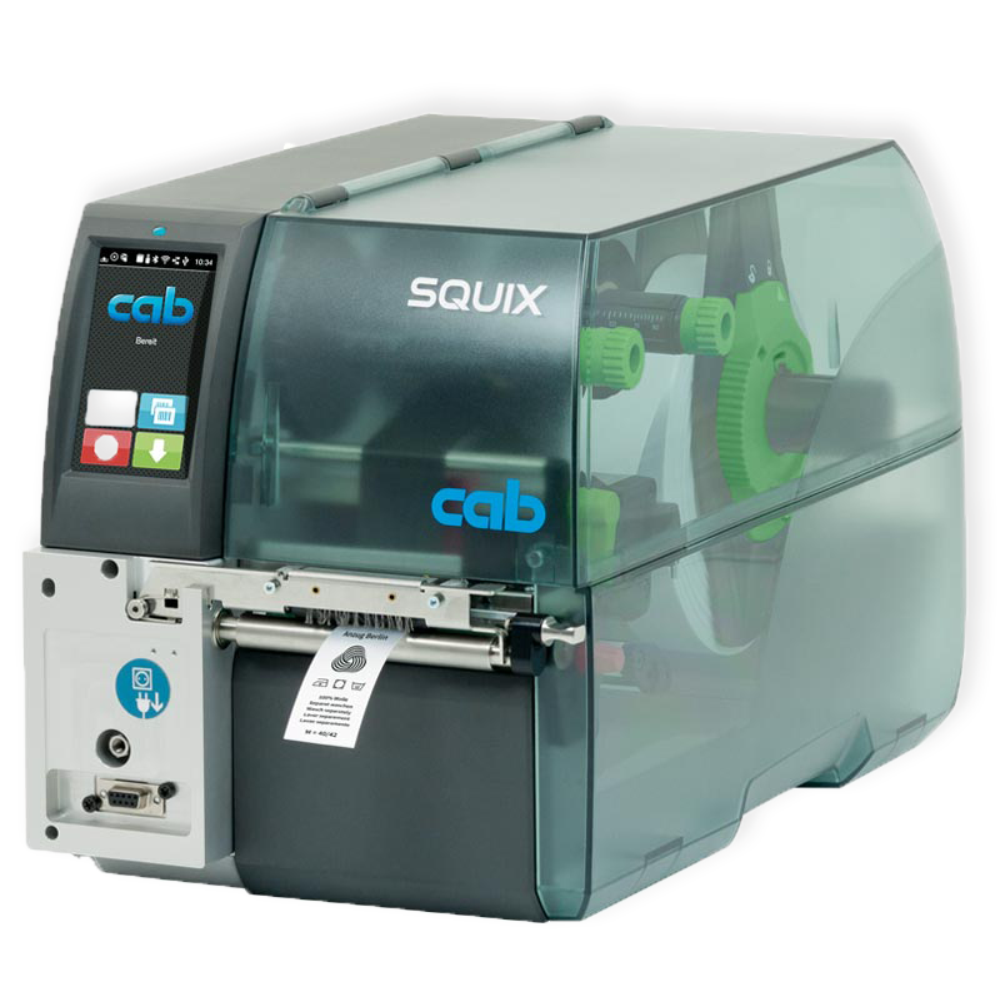

Textile label printer CAB Squix 4MT

- Easy to use

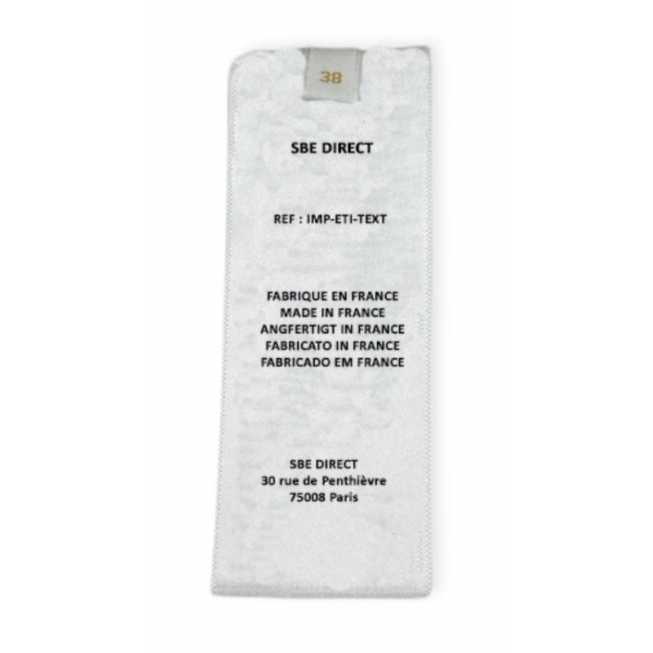

- Textile label printing

- Thermal transfer

- High quality materials

The CAB Squix 4MT textile label printer allows you to quickly print your own professional-quality textile labels. A high-performance textile label printer that delivers high-quality labels tailored to your needs. It is designed for self-printing textile labels while ensuring their durability and quality.

A High-Performance Textile Label Printer

Our CAB Squix 4MT thermal transfer label printer gives you the opportunity to print your own labels, choosing both the quantity and design yourself.

Its compact design combines high precision and exceptional printing speed, reaching up to 300 mm/s. It ensures a print quality ranging from 300 to 600 dpi. The components of this textile label printer, mounted on a cast aluminum metal frame, are perfectly aligned and manufactured in Germany using high-quality materials.

| Resolution (Dpi) | Printing Speed up to (mm/s) | Printing Width up to (mm) |

|---|---|---|

| 300 | 300 | 105.7 |

| 600 | 150 | 105.7 |

A Standalone Textile Label Printer

The textile label printer comes with Cablabel S3 Lite software, allowing you to manage every step of your custom textile label production, from design to printing. A wide range of tools is available for designing high-quality textile labels that meet all your needs.

After saving and storing your textile label information as a file, it can be stored on a computer, USB drive, or even in your textile label printer’s memory. Once all necessary data for thermal label printing is stored in the printer’s memory, the textile label printer can operate independently without being connected to a computer or host system.

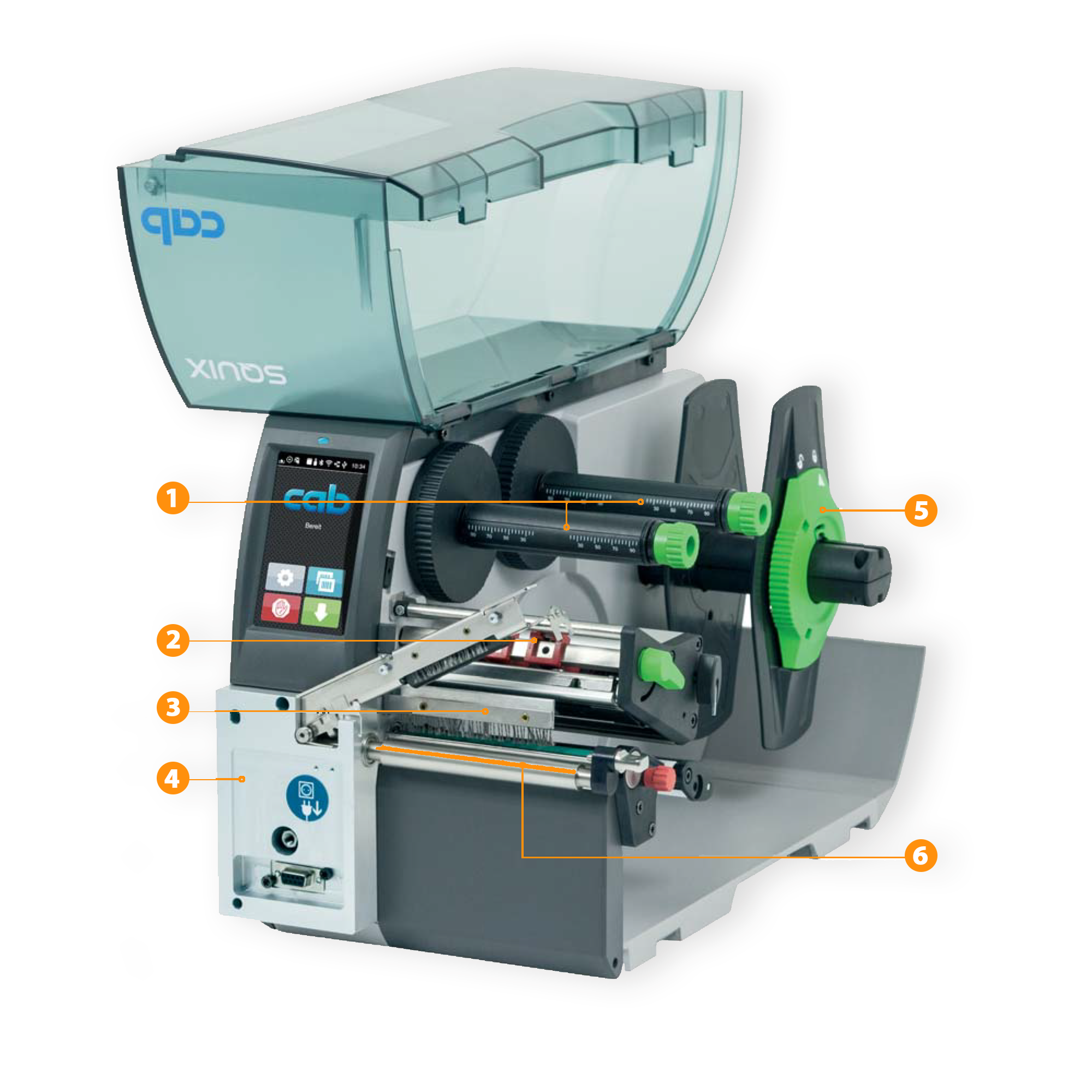

Textile Label Printer Details

1) Ribbon Unwinders and Rewinders: The positioning of the ribbon is facilitated by measurement markings.

2) Pressure Rollers: The two pressure rollers are fixed for all material widths. No adjustment or fine-tuning of the print head is required.

3) Anti-Static Brush: Particularly useful for plastic materials, it eliminates static electricity after printing.

4) Separator: The transfer ribbon may stick to the textile band after printing if the heating temperature is high. The tension roller safely separates the material from the transfer ribbon.

5) Roll Holder: Automatically centers the material roll when the flange is inserted.

6) Material Guide: Ensures precise printing thanks to the material guide located directly before the print roller. The width of the material is adjusted via a screw mechanism.

Discover our textile label printing kit, which includes a CAB SQUIX 4 thermal transfer printer, 15 textile ink ribbons, and 15 rolls of non-adhesive nylon labels.

Software Compatibility: Cablabel S3

CAB printers are fully compatible with the Cablabel S3 software, and we exclusively offer the Cablabel S3 Pro version.

When purchasing a CAB printer, the offer also includes a free version (Cablabel S3 Lite), which allows you to design and print labels. This version is ideal for discovering the basic features before upgrading to the full version.

The Cablabel S3 Pro version provides advanced tools for label design and printing, ensuring optimal integration with CAB printers and efficient management of variable data, barcodes, and complex layouts.

For more details on label printing, check out the following articles:

- Label Rolls: An Essential Consumable for Printing with a Label Printer

- How to Choose the Best Label Printer

- Barcode Label Printers: The 4 Key Questions to Ask Before Buying

- How to Choose a Suitable Ink Ribbon for High-Quality Labeling?

- Price

- From €3315.00 to €3683.00 excl. VAT

- Unit

- the printer

- Conditioning

- Individually

- Guarantee

- 1 year

- Printing

- Direct transfer

- Weight

- 10 kg

- Format

- 252 x 288 x 460

- Printing width

- Up to 105.7 mm

- Max. outer diameter of the roller

- Up to 205 mm

- Diameter of the ribbon mandrel

- 25,4 mm

- Diameter of the roll core

- From 38,1 to 76 mm

- Outside width of the ribbon

- 25 - 114 mm

- outside width of the roll

- 4 - 110 mm

- Print speed

- Up to 300 mm/s

Choose product attributes:

| Ref. | Resolution | Unit price | Buy |

|---|---|---|---|

| IMP-TT-4MT-300 | 300dpi |

1+

€3,315.00

|

|

| IMP-TT-4MT-600 | 600dpi |

1+

€3,683.00

|