Heat press machine

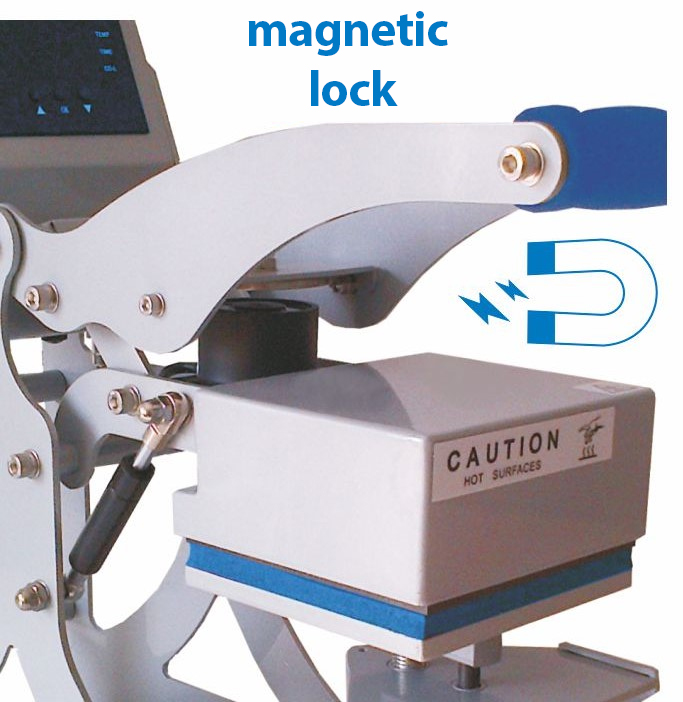

- Magnetic locking

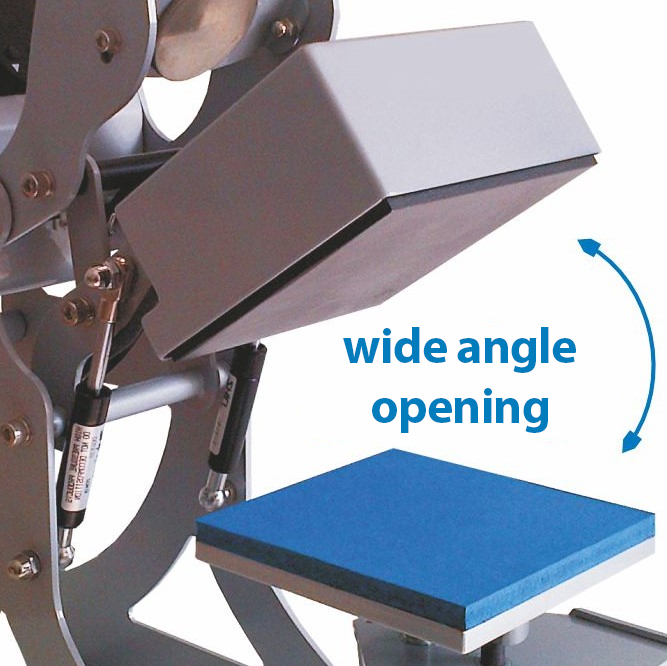

- automatic opening

- Very easy to use

- Temperature and pressure time management

- Digital display

- 3 year warranty

This heat press machine is ideal for heat setting patches, iron-on labels or other ink transfers onto your garments. Known for its ease of use, you will save time and money when customising all types of garments.

This customised marking solution guarantees the traceability of garments and other textile articles thanks to a label with several variables (name, text, barcode, brand, logo, etc.). This technique ensures that the labels are resistant to industrial washing.

How does a heat press machine work?

A heat press machine is an affordable piece of equipment that allows you to heat seal your personalised labels onto your clothing quickly using pressure and heat. The result is very good quality and durable, if not better than other devices.

This heat transfer press is made from steel and is laser cut, making it shock and heat resistant. This heat press machine is suitable for everyday or occasional use and is ideal for small work spaces as it has a small footprint, L.52 x W.25 x H.50, which takes up less space than a conventional press.

There are 2 types of heat presses: a corner opening or a swivel opening heat press.

The latter has an angled opening, as it is done by raising the top plate, which allows a "wallet" opening of about 40 degrees. This is the most common and least expensive model.

It has a power of 600 Watts, 2.7 Amps, 220V which allows for high application pressure.

How to use a textile heat press machine?

You can easily place it on a flat surface (work surface, desk) so that you are at a good height to perform the ironing operation.

Once installed, place the surface of your garment on the 15 x 15 cm heating plate with the patch or iron-on label where you want it. This handling will be facilitated by the wide angle opening allowing you to handle any type of garment (t-shirt, blouse, trousers, etc.) without injury.

Discover our iron-on pre-cut which complete this heat press machine.

Set the time and temperature of the heat press machine.

Set the time and temperature of the heat press machine.

This heat press has a digital display, which is very practical to set the time and temperature from 0° to 240°C to suit your fabric. To do this, you need to press the Mode button at the bottom of the digital display to select one of the settings and thus decrease or increase the value. This makes it easy to control the setting throughout the process and avoid any risk of manufacturing errors.

Assisted by a magnetic lock, you can fold down the top plate with minimal risk of injury because it offers maximum pressure with minimum effort (half the handling of a conventional press). You can see the time countdown during the heating process.

When the heating time is over, the plate opens automatically, which does not require the use of an air compressor.

This operation is very fast and allows you to heat seal labels on a large number of garments, ideal for marking linen in hospitals, laundries, old people’s homes or any type of business.

Finally, this textile heat press machine is made in France and complies with European, UL, ULC and RoHS standards which guarantee safety against fire and electrical risks.

This equipment is extremely reliable and comes with a 3-year warranty.

To choose the ideal heat press for your needs, just ask yourself a few questions:

- How often do you use it?

- What is the quantity per set of presses?

- What type of textile do you use?

- The dimensions of your trays.

Our heat press is very easy to use and of high quality, so you can keep it for a long time. In addition, the transfer time is really fast due to its high power.

If you have any questions about this press, please do not hesitate to contact our customer service.

Heat press or iron ?

Using a heat press machine allows the heat to be distributed more evenly for better adhesion. In addition, this equipment is much more sophisticated than an iron, which means that ironing is safer and faster. The thermal press is recommended for professional use to heat seal large series and to increase productivity.

Discover how this heat press works with this demonstration video.

- Price

- €1500.00 excl. VAT

- Unit

- Thepress

- Conditioning

- Individually

- Guarantee

- 1 year

- Material

- Steel

- Weight

- 16,5 kg

- Consumption / Power

- 600W, 220V

- Dimensions

- L.52 x l.25 x H.50

- Standards

- CE / UL / ULC / RoHS

- Operating temperature

- 0°C to 240°C

Choose product attributes:

| Ref. | Prices | Unit price | Buy |

|---|---|---|---|

| IMP-PRESSE-TEXT | Decreasing |

1+

€1,500.00

|

You might also like