In 2019, more than 2 million new cars were sold in France. In addition, the market for the rental of professional equipment (construction machinery, forklifts, computers, etc.) has increased by 7% over the past year because it represents a lower cost for companies. These sales and exchanges of equipment encourage manufacturers to identify their industrial products and certify their compliance with current European regulations.

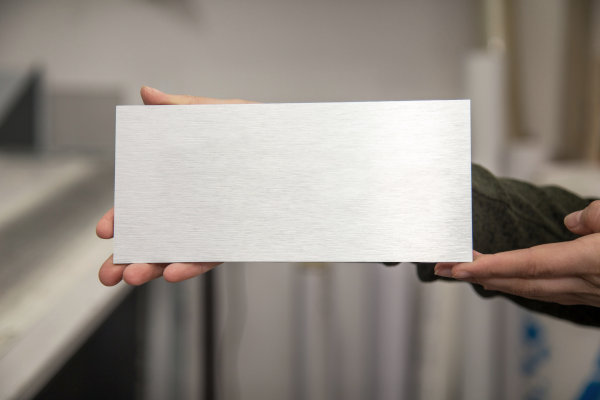

SBE Direct can provide you with affordable rigid aluminum and flexible polyester manufacturer plates with high quality markings and finishes.

What is a manufacturer’s plate ?

Used in the automotive sector, the manufacturers plate is used in other industrial sectors such as aerospace, electronics, oil and gas, audiovisual and telecommunications, construction and earthmoving equipment, mechanical equipment. It allows you to identify your professional goods or to attest the conformity of your products.

This manufacturers plate is compulsory for manufacturers of certain industrial products mentioned by the regulations in force, such as industrial and agricultural machinery and factory equipment. This type of identification plate can also be placed on street furniture and premises signs.

A manufacturers plate represents the identity card of a piece of equipment to ensure maximum traceability in case of displacement or sale, with the following information :

- The serial number

- The country of origin

- Technical information (e.g.: maximum load supported...etc.)

- The CE marking which informs about the conformity to the European standards

A manufacturer’s plate is 8 to 10 centimetres in size and allows your equipment to be identified with your company’s name and logo, thus preventing theft and fraudulent use.

The conformity plate respecting European standards

_1.jpg)

The CE marking is compulsory for certain types of industrial products mentioned in one or more European regulations that explicitly provide for it. Products that are not covered by these regulations are not allowed to bear this marking. The latter allows you to authorise the free circulation of your products on the territory of the European Union and to justify the conformity of your products to European standards.

Once you have assessed the conformity of your products during design and manufacture, you can proceed with the CE marking with the required information such as the technical characteristics and the CE logo.

Our aluminium manufacturers plate is suitable for this type of marking. At an affordable price, our identification plate is available in 2 sizes and with several types of fixation (holes or adhesive). You have the possibility to customize your printing with your own information and visuals, please contact us.

How to choose a manufacturer plate?

There are several types of manufacturer plates, in stainless steel, PVC and anodised aluminium. They can also be available in several colours and can be personalised with your information such as your logo.

A short explanation of the process of anodising aluminium: this consists of thickening the aluminium, so that it has a high resistance to corrosion and high temperatures. As a result, anodised aluminium is an improved brushed aluminium that is more suitable than raw aluminium for use as a transformer plate.

In addition, there are 3 main techniques for engraving a builder’s plate.

- Chemical engraving

This type of engraving is the ideal process for the manufacture of medium or large series with an aesthetic quality. The logos and texts appear in relief or in a matt/glossy effect with an engraving depth between 0.01mm and 0.3mm.

- Laser engraving

Laser engraving is the most economical process due to its speed, which consists of engraving the material with a heat beam. This technique ensures an indelible high definition engraving quality and allows you to engrave small characters or personalise your manufacturer’s plate.

- Mechanical engraving

This engraving is established by CAD (Computer Aided Design) which defines the path of a groove to create the engraving. This process allows a wide range of visuals (logos, texts, pictograms) to be engraved and coloured lacquers to be applied to the engravings, ensuring good legibility and a quality result. This technique is recommended for the production of single items or medium-sized series.

Now that you know the different characteristics of a manufacturer’s plate, you need to define the intended use of the objects, the number of plates you want to engrave or the quality of the engraving you expect, which will help you in your choice.

Remember that a manufacturers plate must be resistant to time and impact. We therefore recommend an aluminium plate, anodised to ensure resistance to UV, corrosion and chemicals. In addition, chemical or laser engraving is recommended as it is suitable for the extreme conditions such as heat, vibration and friction that industrial equipment can endure.

In terms of fixing, we recommend a riveted manufacturer plate so that it is immovable, although adhesive tare plates are also effective due to their high strength adhesive.

It is also important to choose the right size, adapted to the dimensions of the equipment, so that the engraved plate can be easily located and the information is visible.

If the product cannot accommodate a manufacturer plate, you can affix a more flexible manufacturer label to its packaging or documentation.Thanks to its adhesive, it has an excellent hold on many surfaces, especially rough ones and in aggressive environments. It cannot be torn off.

Below is a comparison table of our manufacturer plates and labels.

| Product | Format | Material | Gravure | Fixation |

|---|---|---|---|---|

| Manufacturer plate (rigid) | 75x140mm / 100x50mm | anodised aluminium | electrochemical anodising | adhésive 3M468 /rivets |

| Manufacturer label (flexible) | 75x140mm / 100x50mm / 100x100mm / 100x150mm | thick, glossy polyester | digital printing | double layer acrylic adhesive 3M |

| Tamper proof label (flexible) | 36x46mm | thick, transparent polyester | digital printing | instant cyanoacrylate adhesive |

Where to place a manufacturers plate?

For your machines and equipment, we recommend that you place the manufacturers plate on an unmovable part of the vehicle, such as in the engine compartment, in the boot or on the right-hand doorpost. It should be easily accessible in the event of a technical inspection or conformity check.

Please contact us to find out more about manufacturers plates and to request a quote for your manufacturer plates.