Throughout your navigation in our product catalogue, we offer you to receive samples or loans of our products free of charge, so that you can easily evaluate, compare, and test our products. But that is not all. Now, here’s what to do.

Why compare? Why should you test?

1) Testing our products in real conditions on site.

This is the only way you can ensure that you are satisfied with the intended use of the products you plan to order. This is particularly important for adhesives, materials and label printing if you have to put them in challenging conditions (exterior, chemical environments, heat…).

2) Evaluating the quality of our products.

Making the right decisions is becoming difficult, there is such a variety on offer, but sometimes this can be misleading. As a result, we strongly encourage our clients to test, evaluate, and review our products and judge for themselves. The high quality of the products we present here is our best marketing, the quality is immediately apparent.

3) Comparing our products with others on the market.

For all the products we offer, you will find products that appear to be of equivalent quality, but in fact the disparities are often large. For example, simple aluminium labels are often marketed with large varieties of thickness, adhesives, and printing quality, of course at very variable prices. Similarly, for physical safety systems, some low-cost cables fall far from providing any real security. We offer only rigorously selected products here, with a high, actually very high quality. We are not afraid of comparison, quite the contrary, we encourage it.

How do I test your labels and stickers in a professional manner?

1) Testing the adhesive

The most important thing is to understand that you must never try to remove a label that has just been applied. The adhesives used are only effective 72 hours after installation. Without going into too much technical detail, there is an unavoidable need for polymerization time for the glue (chemical transformation in contact with the surface) and a time for "anchorage" in which the glue is going to become encrusted in the irregularities of the surface (the harder the adhesive is, the longer this process, but the better the adhesion).

It is important, to affix the label or sticker well, ensuring that the surface is clean and dry.

A 3M degreaser (sold separately) is provided with the samples. It is important to use it (especially for a test) since it allows the surface to be prepared better to receive the adhesive, thus providing a maximum adhesion. For more information: " SBE advises you/Affix a label so that it will remain for a long time“.

To compare two or more different labels, it is important that they be glued to the same surface, and to wait 72 hours before any removal test, and to perform the tests at the same time.

However, if these labels or stickers are to be placed on a wide variety of surfaces (metal, wood, plastics, etc.), it is important to test all these surfaces. While we use the most universal adhesives possible, some adhesives will offer a better grip on certain surfaces.

The principle is the same for surfaces with temperature extremes (extreme cold, high temperatures), adhesives can react differently, tests are very important.

Finally, the thickness of the adhesive is key on grainy or irregular surfaces. Most labels on the market, such as our “basic-price” or entry level products, offer a 20 micron adhesive thickness. Our " double adhesive" labels and stickers actually offer a thickness of 90 microns, more than four times the standard thickness. Our aluminium and steel metal plates are equipped with an adhesive 127 microns thick. It’s this difference in thickness that will make it possible to have quality adhesion if the surfaces are irregular. Here too, removal tests are important.

2) Testing the label or sticker

The surface is the very substance of the label (polyester, polyethylene, aluminium…).

For aluminium plates, for example, the rigid version is much harder to remove because it can only be pulled off with one grip, not by twisting a corner. For security seals, check that the desired effect (Void, destructible, sealed…) is correctly applied on the surface type you will use.

Finally, presentation is very important. These labels or stickers are intended to be seen, and almost always represent the image of your company. The surface plays a big part in the final presentation of the label.

3) Testing printing

We use many techniques to print these labels, whether for variable data (barcode, numbering) or for graphics (logos, presentation). Whatever techniques are used we take the greatest care over the final quality of the printing both in its durability and in its finish.

The mechanical durability of the printing is very important, and you can perform a few simple tests to verify that inscriptions hold firm (manipulation, scratching, scrubbing, applying chemicals that might be used, strong temperatures, exterior - UV), depending on what you use your labels or stickers for (desktop, industrial, chemical, etc.). For the most difficult environments, transparent protection is often necessary.

The quality of the printing is seen by the finesse of the rendering of the product, the finesse of the rounding (no gradation) and the accurate rendering of colours, identical to the colours of your graphic chart, and finally through the vividness of the colours.

4) Testing transparent protective covering

This protection must offer excellent look and it must not be possible to “delaminate" the label, in other words to remove this protective covering. If the label is of poor quality, it is easy to remove this protective covering with a cutter, and over time it can even "peel" itself. Here too, the tests are important. For all our "protected" labels, we use 50 microns or more hot-glued protective covering. Test and compare yourself.

For labels that do not include transparent protection, we offer these optional self-adhesive protective covers of different sizes. They are often useful if you intend to add manual inscriptions on the label, or for difficult environments. It is often preferable to choose a slightly higher protective cover size than the label so that it covers the label generously.

In all cases, transparent protection must be sufficiently thick to protect the label and print. All the protective coverings we offer are 50 microns thick, offering high level protection. However, the more standard labels you can find on the market usually have a protection of 25 microns or less.

How should I actually compare physical security systems?

Physical security systems are more complex to assess because break-in tests need to be conducted, and not everyone has the knowledge or tools to conduct them. Unfortunately, it is often the thieves themselves who carry out these break-in tests on companies that thought they were well equipped with security systems and who only then realize that the quality of a security system can have very large variations.

We therefore offer our customers the widest possible range of security products (low cost products, high security, very high security…). This range policy helps you to realize that there are very different levels of quality, that each level of quality corresponds to a given level of security, and it is up to the customer to make this choice according to the level of protection he/she wishes to bring to the company.

The ranges we present here offer you an idea of what can done for such a price or level of security, to make quality and price comparisons. You will understand that it is useless to compare a "Very High Security" product of our range with a “budget" product of a competitor, apparently cheaper, based on a simple visual likeness in the photo.

These are the reasons why a phase of basic visual and tactile testing is generally sufficient to make your choice. What is essential to look at is the following:

- The thickness of the steel cable (alone, excluding plastic covering), which defines a level of security (usually 4 mm, 6 mm and 8 mm in diameter).

- Locks, completely metallic, offering better security than those in plastic casing. Steel locks, much more robust, are the best (and most expensive) locks in contrast to zinc or aluminium locks (the most common ones). A simple magnet stuck on the lock will tell you that whether it is steel (iron compound).

- Circular keys are much more difficult to reproduce than flat keys.

- The proper finish on the tip of the lock to be fixed in the security slots for laptops. This is a very important point of testing for this type of product, Sometimes the tips do not hold at all or offer too much give.

- The thickness of the lock for "light" laptops (a lock which is too big will make the laptop wobble).

- Padlock size (for desktop security): 30 mm is the standard size, but we also offer 40 mm and 50 mm padlocks. This size defines a security level

- Padlocks must be made of reinforced steel (more durable). Here also a test with a magnet will tell you the metal of the padlock.

- For combination locks, a minimum of 4 dial discs is essential for good security.

- The quality of anchorage plates: the best security levels are obviously with metal plates with a hard rubber patina, attached with cyanoacrylate glue (avoid plastic plates that melt in heat!). The greater the gluing surface in sq cm the better the resistance to removal. If the anchorage plates can be screwed in, with screws being protected or unremovable, the security level increases greatly. Plastic anchor plates or simply stickers offer a low level of security.

- The length of the cables is also important in the installation of the systems. The shorter the cable, the cheaper the system, but it will be less practical for use.

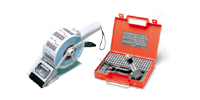

We offer our customers loans of security products so that they can perform these quality tests or possibly to compare our products with those of the market. However, some customers may wish to carry out further testing of these safety products, and we strongly encourage them to do so. Testing our products in real conditions of removal and tampering is often impressive, so their effectiveness is important. However, you will need a professional tool to conduct these tests, and a simple DIY tool will not result in a real result, except to reassure you about the effectiveness of our products, which is in itself a good thing.

For obvious reasons, we cannot provide new products free of charge to our customers only for testing purposes. In these cases, we offer you to purchase a copy, and we will offer you the shipping costs with pleasure (contact us).

Finally, it must be understood that these security products have different degrees of security and that no security system is completely impenetrable. In the profession we are assess these levels of security by the notion of “penetration time". The ultimate goal is that in the event of tampering, physical security systems are slow and complex enough to penetrate that losses are minimal or even nil. It is on this principle that you must base your choice of the best level of security you want to bring to your property in line with your budget.