The leading ready-to-wear group, Inditex, made up of 8 brands (Zara, Pull & Bear, Massimo Dutti, Bershka, Stradivarius, Oysho, Uterqüe), has been unexpectedly successful, with a turnover of 21 billion euros at the end of 2020, much better than many market players. Despite the health crisis, which led to the closure of 640 sales outlets, Pablo Isla’s group has stood out thanks to RFID and the digitalisation of its business.

INDITEX’s secret weapon: RFID

Since 2016, RFID (Radio Frequency Identification) has been deployed within the group’s brands. The first to be affected is Zara, a brand recognised internationally for its renewal of collections similar to those of the great designers. The first application of RFID was in the brand’s flagship store in Soho where it was possible to pay for purchases directly in the fitting room. An innovation in terms of customer experience that allows the customer to skip the checkout and thus make the customer journey more fluid.

RFID in inventory management

As a reminder, RFID technology is implemented by inserting a chip into a product that stores its data. It can be read remotely, making it possible to follow the route of the garment and its location. It saves a lot of time, especially for those brands that have to manage a large stock of clothes due to the constant renewal of collections.

For example, Zara has inserted this technology into its EAS hard tags with the information of each product. In addition, each point of sale has its own mini data centre to optimise processing speed. This is known as "edge computing", which advocates simplified use of data by users.

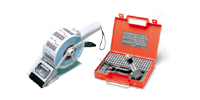

These rigid labels are placed on the garments in the various production sites. These garments then go to the central logistics centre in Spain where the tags, supplied by Checkpoints Systems, are encoded. The advantage of this is that the contents of the boxes can be checked without opening them and the destination of the shipments can be changed at the last moment according to the demands of the shops. The figures speak for themselves: the in-store inventory is completed in 2 hours, compared to 24 hours before this new system. Indeed, all you need is a portable RFID reader to scan the tags. The data is recorded in real time in the inventory software.

RFID in the sales process

This geolocation of products allows the optimization of service and customer satisfaction. Indeed, thanks to RFID coupled with a barcode, the customer can check the availability of a model in real time in the shop or on the website by scanning the label via his smartphone. In addition, the presence of a barcode makes it easier to return an item.

In addition, the development of RFID has led to the redesign of checkout. In some shops, such as Zara in Soho, items can be placed on the counter of the self-checkout machine and are each recognised by their RFID tag containing their data. The items are automatically displayed on the screen with their prices, and all that remains is to proceed with payment. The RFID tags are reusable several tens of thousands of times, so they are sent back to the production sites once their coding is reset to 0.

Online sales are also impacted by RFID. Indeed, it makes it possible to give the availability of products in real time. So, depending on where an order was delivered, products would leave the shops rather than the warehouses. This allowed for great efficiency as products were delivered faster and the carbon footprint was reduced. In COVID’s time, RFID has been very effective allowing INDITEX to record a 74% increase in online sales in the second quarter of 2020.

The benefits of RFID

RFID is becoming the standard for such a market, the textile and clothing industry. Using this technology is a competitive advantage due to several benefits:

- Reduction of fraud and theft

- Verification of the contents of supplier receipts without manipulation

- Modification of the tracking according to demand or climatic hazards

- 80% reduction in the time spent on inventory

- Intelligent inventory in real time

- 50% reduction in checkout time

- Improved service quality and customer satisfaction

To conclude, INDITEX has been ahead of its competitors since 2016 by installing RFID in its supply chain. This gives it an undeniable competitive advantage by being agile, flexible and omnichannel to meet the new challenges of the market.