Would you like to personalise your products with a logo? Or add a mandatory statement? Industrial marking is essential to identify goods and your brand. In this article, discover the different marking techniques adapted to your needs and the materials to be marked.

What is the purpose of industrial marking?

Industrial marking allows a large number of materials to be marked durably: wood, metal, plastic, etc. The objective of personalising a support is to optimise the traceability of parts or products and improve the brand image.

This marking makes it possible to mention the origin, the conditions of care or maintenance of the products. This technique is used in many sectors of activity such as aeronautics, medical and automotive.

Marking is also used for marketing purposes to highlight a brand by affixing a logo, a slogan or an image on a T-shirt, a banner or any other support to be visible to potential customers.

What are the branding techniques?

There are a variety of branding techniques that can be used to achieve a result that is suitable for a particular use, whether permanent or not.

Here are the permanent marking techniques:

- Laser marking

This technique is the best known for marking media in a regular and unalterable manner. The process consists of engraving a part with a laser in a very precise way on any type of support such as plastic, metal, wood, glass, paper, rubber, cardboard, etc. It is a computerised method which allows the pattern to be defined on the computer and the laser action to be automated.

- Micro-percussion marking

The principle of this technique is based on a succession of points made by punches on the part to be marked to form letters, numbers or other codes. This technique is also definitive on metals, plastic, wood or concrete.

- Electrochemical marking

This marking technique is used on conductive metals such as stainless steel, aluminium, inconel and titanium. This marking is achieved by a chemical reaction between the metal and an electrolyte.

- Scribing marking

In this technique, a punch is used to continuously engrave the marking on steel and plastic. The engraving is deeper than that obtained with micro-percussion marking.

- Marking by striking

This technique consists of striking the material with boxes containing engraved characters or punches. This marking is simple and quick to carry out for a permanent recessed result on steel, stainless steel, plastic, leather and wood. Discover our cold stamping kit which contains all the necessary material to identify your goods permanently.

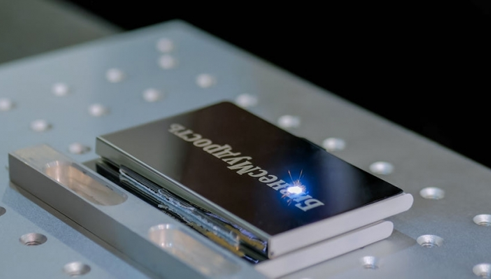

- Hot stamping

This technique consists of applying a heating block containing the characters of your choice to the material to be marked, such as plastic, cardboard, rubber, leather and wood. Discover our hot stamping pen to engrave your computers, screens, telephones, machines permanently.

If you prefer a lighter and more superficial marking, you can opt for 2 techniques:

- Inkjet marking

This process consists of projecting ink onto the material without contact, ideal for marking irregular or fragile surfaces. This technique can be used on any material, even textiles.

- Marking by paint jet

This is a projection of paint onto a surface using a machine which allows large irregular or hot parts to be personalised. The result is very contrasting and visible.

The firm plate for an effective marking

To carry out a marking, it is important to choose the right materials on which the information will be visible.

We recommend that you choose aluminium labels, also known as metal manufacturer’s labels, which can be stuck to any type of surface thanks to its very strong 3M adhesive. They can be used to identify electronic devices, vehicles, machines on the production line that require seamless traceability. It has high resistance to abrasion, solvents, high pressure cleaning and extreme temperatures for long lasting effectiveness.

These manufacturer’s plates can be engraved with information such as the owner’s name, a serial number, a barcode, technical specifications, or a CE marking to attest to the conformity of the products. This marking may be compulsory for certain industrial products mentioned by the European regulation. These manufacturer’s labels can be personalised using laser technology for an indelible rendering at a very low cost or by electrochemical anodisation for a deeper engraving.