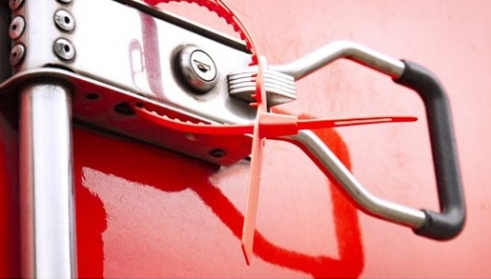

The plastic seal with progressive tightening is used in many fields, such as logistics, transport, emergency exits, fire extinguishers, medicine cabinets... their operation may seem imprecise and confusing, we will understand in which context it is preferable to use this type of seal and also understand their opening/closing system.

An easy to use disposable plastic seal

Unlike security seals for transportation or some padlock seals, plastic seals do not meet the ISO 17712 standard, they have no international security value. They are "small security" seals, used in companies and can easily be removed manually.

They are intended to be used once and only once without claiming to secure the product.

To lock and identify products

The real use of the plastic seal lies in identification. Indeed, due to its low tensile strength, it is easily torn. It does not protect its contents by its resistance but by its identifier written on its plate.

Generally, disposable plastic seals are required for the transport of a bag or sack as well as for the fire extinguisher (NF EN 3 standard), meters, safety valves and circuit breakers. Indeed, if the seal no longer has the correct sequential number then it is clear that the contents of the bag are compromised.

How to lock a plastic seal

There are several ways to remove a plastic seal:

- By crushing: with a suitable pair of pliers. 130 mm sealing pliers. This product has a small strength, only 3kg of pull is enough to break the buckle.

- By notching: thanks to the acetal insert and the notched rod, the progressive tightening locks the rod definitively in its place. Once the seal is installed, it is no longer possible to loosen or remove the seal without breaking it.

- Anti-return insert: this metal insert locks the smooth rod in the hole. The insert retracts onto the stem, preventing any backwards movement.

How to open the plastic seal?

The snap lock product includes the side tear off system which includes a side tab, which allows side opening by manual tearing. Simple, easy and fast.

Crush seals and non-return inserts have little tensile strength, just pull with force to remove or even with a simple pair of scissors.

For our plastic lead seal has a small strength, only 3kg of pull is enough to break the loop. It is easy to break by hand with just the drill of our hands.

The side tab security seal has a better strength. The notch adds tensile strength, for this product a force of 8kg should be applied to break it.

Our security seal for luxury products is stronger than the previous seal. It can withstand up to a 12kg pull. For some, the use of scissors will be necessary.